AQUAESTIL

ROBOTIC GRINDING OF BATHTUBS

Due to the increased amount of work, the lack of manpower and difficult working conditions, Aquaestil, the company manufacturing bathroom equipment, was looking for a solution for sanding and polishing bathtubs.

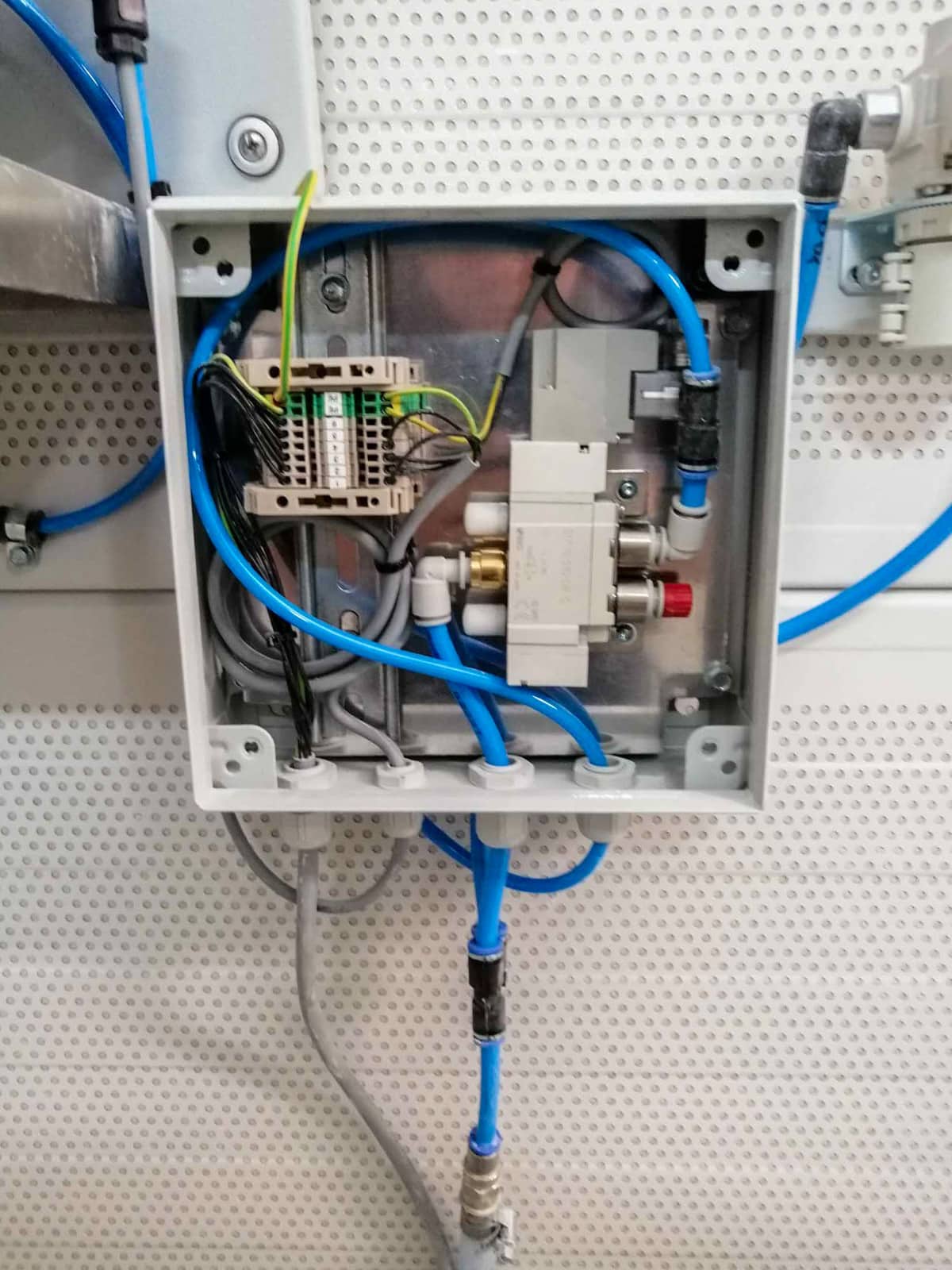

At Nopromat, we designed a solution with a robotic cell with a Fanuc robot. There is also an ACF (active contact flange) located on the robotic arm. This is an active interface, which ensures that there are no grinding errors during grinding and maintains a constant grinding force. The robotic cell also enables automatic tool change:

- two pneumatic eccentric grinders of different dimensions

- electric polishers

We also made a dispenser for automatic dosing of polishing paste on the polisher.

The cell consists of two cabins, which allows the operator to insert the bathtub into cabin 1, while the robot can process the bathtub in cabin 2 and vice versa. The cabins are physically separated by a lifting door.

The entire cell is controlled by a Siemens controller.

With the integration of the robot, the company has significantly accelerated the sanding process and reduced the cost of sandpaper, as due to robotization and the use of ACF there are no grinding errors that would in turn destruct sandpaper.

Due to the increased amount of work, the lack of manpower and difficult working conditions, Aquaestil, the company manufacturing bathroom equipment, was looking for a solution for sanding and polishing bathtubs.

At Nopromat, we designed a solution with a robotic cell with a Fanuc robot. There is also an ACF (active contact flange) located on the robotic arm. This is an active interface, which ensures that there are no grinding errors during grinding and maintains a constant grinding force. The robotic cell also enables automatic tool change:

- two pneumatic eccentric grinders of different dimensions

- electric polishers

We also made a dispenser for automatic dosing of polishing paste on the polisher.

The cell consists of two cabins, which allows the operator to insert the bathtub into cabin 1, while the robot can process the bathtub in cabin 2 and vice versa. The cabins are physically separated by a lifting door.

The entire cell is controlled by a Siemens controller.

With the integration of the robot, the company has significantly accelerated the sanding process and reduced the cost of sandpaper, as due to robotization and the use of ACF there are no grinding errors that would in turn destruct sandpaper.

We have obtained subsidy for the operation “Digital Marketing Voucher”.

The investment – developing a website – is co-financed by the Republic of Slovenia and the EU European Regional Development Fund.